-6%

-20%

-4%

$2,598.47

$1,127.64

$468.21

$1,029.58

-3%

-6%

-5%

$2,868.12

$1,323.75

-9%

-3%

$2,745.55

-12%

-5%

$102.08

-14%

$1,778.37

-4%

$2,316.78

-7%

$2,088.58

-13%

$797.81

-2%

$3,118.16

Ultraviolet (UV) rays are part of the light that comes from the sun.

The UV spectrum has a higher frequency than that of visible light and a lower frequency than that of X-rays. This also means that the UV spectrum has a larger wavelength than X-rays and a shorter wavelength than visible light and in order of energy, from low to high, are visible light, UV, then X-rays.

As one of the water treatment technologies, UV is known to be an effective disinfectant due to its strong bactericidal (deactivation) ability. UV disinfects water containing bacteria and viruses and can be effective against protozoa such as, Giardia lamblia cysts or Cryptosporidium cysts. UV has been used commercially for many years in the pharmaceutical, cosmetic, beverage and electronic industries, especially in Europe. In the US, it was used to disinfect and treat drinking water in the early 1900s but was abandoned due to high operating costs, unreliable equipment, and the growing popularity of chlorination. variable.

Because of safety issues related to chlorination dependence and improvements in UV technology, UV has been increasingly accepted in municipal and household drinking water treatment systems. There are very few large-scale UV water treatment plants in the United States, although there are more than 2,000 such plants in Europe. There are two types of sterilization systems that are NSF certified and classified under Standard 55 - Class A and Class B Units.

Class A - These UV water treatment systems must have an 'intensity & saturation' rating of at least 40,000 uw-seconds/cm2 and be of a design that allows them to disinfect and/or eliminate microorganisms objects from contaminated water. Affected contaminants must include bacteria and viruses

"The Type A entry and use point systems covered by this Standard are designed to inactivate and/or eliminate microorganisms, including bacteria, viruses, Cryptosporidium oocytes and Giardia cysts, from contaminated water"

Class B - These UV water treatment systems must have an 'intensity & saturation' rating of at least 16,000 uw-seconds/cm2 and be of a design that allows them to provide germicidal treatment Water supplements have been deemed "safe". ie no high levels of E. coli. or the number of standard dishes is less than 500 colonies per 1 ml. NSF Standard 55's "Class B" UV systems are designed to operate at minimal doses and are intended to "reduce only non-pathogenic or nuisance microorganisms." "Class B" or similarly unrated UV systems are not intended to disinfect "microbiologically unsafe water".

So the type of device depends on the situation, the source of your water and the quality of your drinking water. The amount of transmitted UV light is affected by the clarity of the water. Drinking water treatment facilities depend on the quality of the raw water. When turbidity is 5 NTU or more and/or total suspended solids are greater than 10 ppm, water should be pre-filtered. It is generally recommended that you install a 5 to 20 micron filter before using a UV sterilization system.

Principles of ultraviolet disinfection - Water treatment at home

UV radiation has three wavelength regions: UV-A, UV-B and UV-C, and this last region, shortwave UV-C, has bactericidal properties for disinfection. Fluorescent-like low-pressure mercury-arc lamps produce UV within 254 manometers (nm). One nm is one billionth of a meter (10^-9 meters). These lamps contain elemental mercury and an inert gas, such as argon, in a UV transmission tube, usually quartz. Traditionally, most mercury arc UV lamps are referred to as "low pressure" type, because they operate at a relatively low partial pressure of mercury, a low overall vapor pressure (about 2 mbar), Low outside temperature (50-100oC) and low power. This lamp emits nearly monochromatic UV radiation at a wavelength of 254 nm, which is within the optimal range for the absorption of UV energy by nucleic acids (about 240-280 nm). In recent years, medium pressure UV lamps operating at much higher pressures, temperatures and power levels and emitting a higher UV energy spectrum from 200 to 320 nm have been marketed. However, for home UV disinfection of drinking water at the household level, low pressure lamps and systems are perfectly suited and even preferred over medium pressure lamps and systems. . This is because they operate at lower power, lower temperatures and lower costs while being highly effective at disinfecting enough water for daily household use. An essential requirement for UV disinfection with light systems is availability and reliability

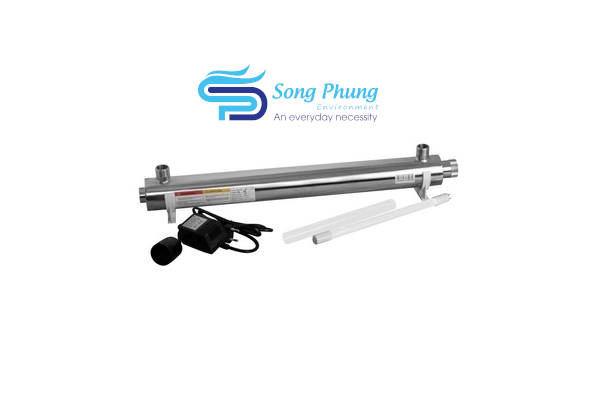

UV system maintenance

Since UV radiation must reach bacteria to inactivate them, the housing containing the light source must be kept clean. Commercial products are available to wash the device to remove any plaque on the light source. Overnight cleaning with 0.15% sodium hydrosulfite solution or citric acid will effectively remove such plaques. Some units have wipers to aid in the cleaning process. UV systems are designed for continuous operation and should only be turned off if not needed for several days. It takes a few minutes to warm up the lamp before the system is used again after shutting down. In addition, the plumbing system of the lamp housing needs to be thoroughly rinsed after a period of non-use. Whenever the system is serviced, the entire plumbing must be disinfected with chemicals such as chlorine before using the UV system to disinfect. UV lamps gradually lose their effectiveness with use, so clean the lamp periodically and replace the lamp at least once a year. It is not uncommon for a new light bulb to drop 20% in intensity within the first 100 hours of operation, although that level is maintained for the next several thousand hours. As stated previously, units equipped with properly calibrated UV detectors will alert owners when light intensity drops below a certain level. Treated water should be monitored for coliform and heterotrophic bacteria monthly for at least the first 6 months of equipment use. If these organisms are present in the treated water, the lamp intensity should be checked and the entire plumbing system should be disinfected with chemicals such as chlorine.Fast facts on UV Water Treatment

1. UV disinfection does not add chemicals to the water. 2. UV is effective against bacteria and viruses; and can be effective against Giardia lamblia or Cryptosporidium if the system is custom designed to meet these sterilization requirements. 3. Ultraviolet sterilization without residual sterilization. 4. Minimum lamp brightness 16,000 µwatt-seconds/cm^2. 5. UV is usually the last unit in a treatment convoy of water treatment equipment. 6. The UV device must have an audible UV detector to notify the user when the lamp intensity is not enough. 7. Regular lamp maintenance and replacement is essential.Capability of the UV sterilization system

UV is a head in 1 system that treats all water used in the home. Capacity ranges from 0.5 gallons per minute (gpm) to several hundred gpm. Since bacteria can be masked by particles in the water, pretreatment may be required to remove turbidity. There is also a limit to the amount of bacteria that can be treated. The upper limit for UV disinfection is 1,000 total coliforms/100 mL water or 100 fecal coliforms/100 mL.

Special considerations

Pre-filtration is necessary to remove color, turbidity and microbial shielding particles from the UV source. Water containing high mineral content can coat the lamp sleeve and reduce the effectiveness of the treatment. Therefore, it may be necessary to pre-treat with a water softener or phosphate spray system to prevent mineral buildup on the lamp. Table 3 lists the maximum levels of some pollutants allowed for effective UV treatment.General recommendations

Installing a UV treatment system, or any other water disinfection system, is no substitute for proper well design and construction. If you have a dug well as well as a supply, replacing the well is probably a more satisfactory long-term option. If a dug well is your only supply option, consider all treatment options before you decide what to do. Make sure you get advice from an expert!Selection of recommended water treatment process:

1. Get information about your water source.

2. Test Your Water - At least Every Year

3. Determine which problems are related to equipment failure, i.e. cracked housing, no cover, improper sealing, poor surface drainage, etc. Make the necessary repairs and improvements to the system.

4. Install necessary drinking water treatment systems. I have provided several links online for water treatment systems, but I always recommend a preliminary water test.

x

x