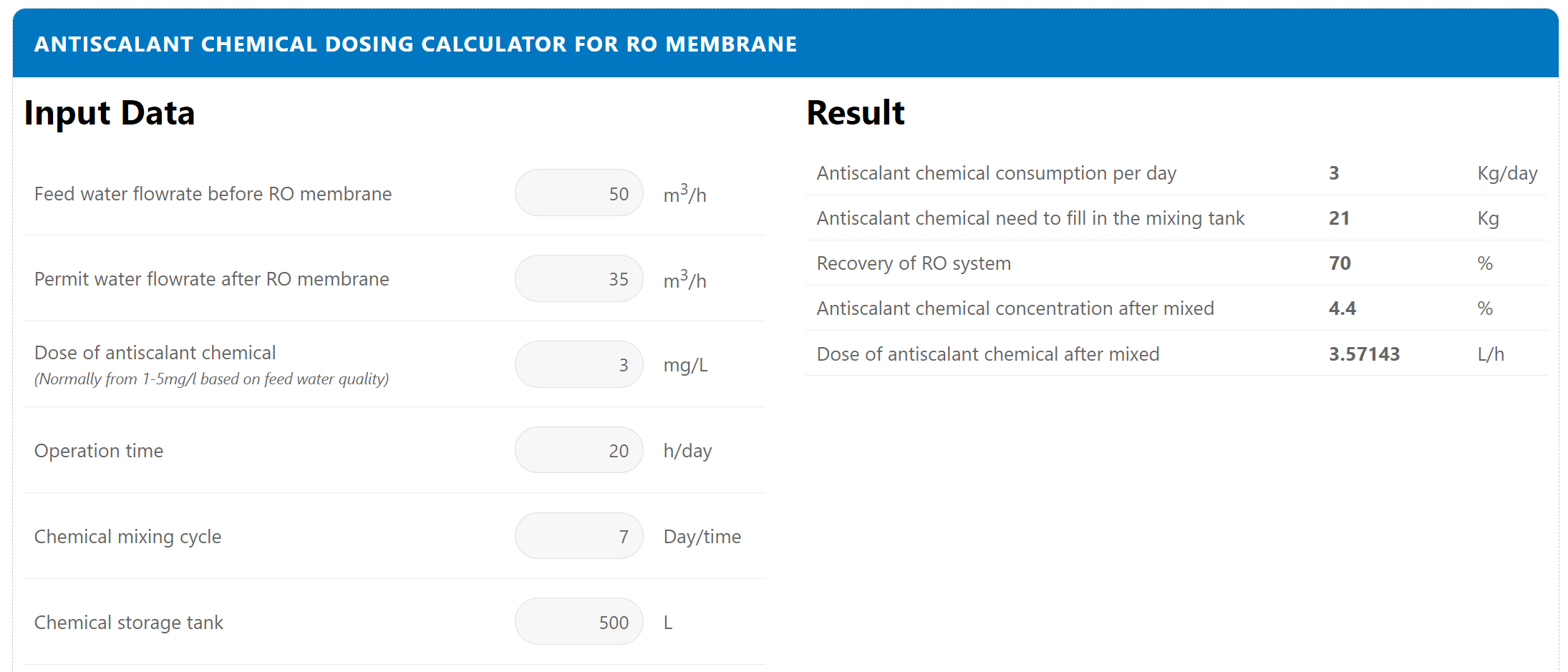

How to use utility for calculation antiscalant chemical for RO membrane

What is an anti-scale chemical and how does it work?

Instructions for using the utility to calculate the dosage of RO membrane anti-scale chemicals by pictures

Calculator utility interface:

Input Data

| Feed water flowrate before RO membrane | m3/h | |

| Permit water flowrate after RO membrane | m3/h | |

| Dose of antiscalant chemical (Normally from 1-5mg/l based on feed water quality) |

mg/L | |

| Operation time | h/day | |

| Chemical mixing cycle | Day/time | |

| Chemical storage tank | L |

Result

| Antiscalant chemical consumption per day | 0 | Kg/day |

| Antiscalant chemical need to fill in the mixing tank | 0 | Kg |

| Recovery of RO system | 0 | % |

| Antiscalant chemical concentration after mixed | 0 | % |

| Dose of antiscalant chemical after mixed | 0 | L/h |

Step 1: Enter the inlet water flow before passing the RO membrane, the unit is m3/h

Step 2: Enter permit water flow after RO membrane, unit is m3/h

This index depends a lot on inlet water quality, pretreatment process, RO system design (1 stage or multiple stages, 1 pass or 2 pass).

Step 3: Enter the dose of anti-scale chemical, in mg/l or ppm.

Step 4: Enter operating time, unit h/day.

This is the time of the water treatment system operates in 1 day, it can be 6, 10, 15, 20, 24 h/day

Step 5: Enter the cycle for refill chemical, in units of days/times.

This is the cycle time you need to mix chemicals once, for example, if you want to mix once every 10 days, choose 10

Step 6: Enter the volume of chemical mixing tank, unit L..

On the right is the column that returns the results

- The amount of chlorine chemicals used in a day is 3kg/day

- Amount of chemicals to be mixed into the tank: 21kg for each cycle

- Recovery rate of RO system: 70% (mean 30% discharge to drainage or reuse)

- Concentration of chemicals after mixing: 4.4%

- Flow of anti-scale chemical to be filled: 3.57 liters / h, this is the flow you set for the metering pump to fill the water