Birm – Filter media

$64.40 $61.51

Birm – Filter media

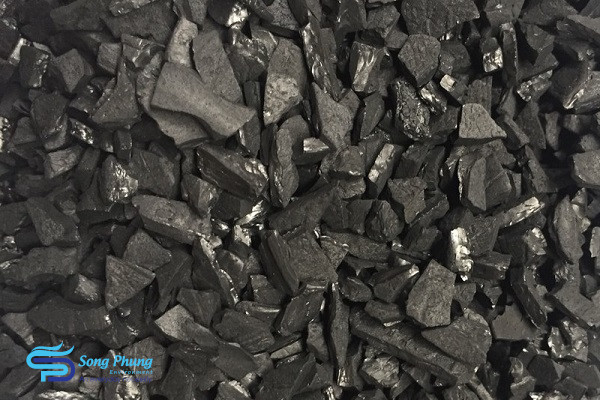

– Characteristics: Dark brown granules, hard, dry loose

– Density: 1.0 – 1.2 Kg/L

– Standard size: 0.5 – 2 mm

– Iron adsorption: 9.5 mg/g

– Arsenic adsorption: 0.2 mg/g

– Working pH range: 6.8 – 8.5

– Required material layer height: 1200 – 1500 mm

– Effective filtration speed: 10-20 m/h.

– Required backwash speed: 30-40 m/h

– Specification: 20 kg/bag

– Origin: USA

Birm – Filter media

– Characteristics: Dark brown granules, hard, dry loose

– Density: 1.0 – 1.2 Kg/L

– Standard size: 0.5 – 2 mm

– Iron adsorption: 9.5 mg/g

– Arsenic adsorption: 0.2 mg/g

– Working pH range: 6.8 – 8.5

– Required material layer height: 1200 – 1500 mm

– Effective filtration speed: 10-20 m/h.

– Required backwash speed: 30-40 m/h

– Specification: 20 kg/bag

– Origin: USA

Specification:

– Acts as an insoluble catalyst to remove Iron, Manganese, Arsenic and some heavy metal compounds dissolved in water.

– Surface can be easily cleaned by backwashing to remove precipitates

– Characteristics: granular, dark brown, hard, dry loose

– Hard to dissolve in iron reactions, long using time and low material consumption

– Any type of heavy metal present in the water will also affect the health of the user. Because these metals cannot be absorbed by the body nor excreted.

– Specialized birm beads remove Iron, Manganese, Arsenic and some heavy metal compounds dissolved in water.

– Birm beads is a MnO2 manganese dioxide coated aluminum silicate filter material. This coating is a highly oxidizing compound that acts as an insoluble catalyst to enhance the oxidation reactions of Fe2+ to Fe3+ and produce precipitated Fe(OH)3 iron hydroxide (alum) and adhere to the surface. birm seeds in layers.

– The surface of birm seeds can be easily cleaned by backwashing to remove precipitates, so it is necessary to have a filter pump with sufficient pressure to dislodge iron precipitated from the grain surface.

Advantage of birm:

Using birm particles is an effective and economical filtration solution compared to other current filter materials:

– High catalytic efficiency leads to very effective filtration of alum and manganese in groundwater

– Hard to dissolve in iron reactions, long using time and low material consumption

– Safe for users because it does not dissolve in water

– Wide temperature range

– Can be used in both gravity filtration or pressurized water treatment with a composite filter column or a stainless steel filter column using a control valve

– No need to use chemicals for material regeneration

– Birm increased capacity with existing clean water treatment plants and stations by 1.5-2 times without the need to install new filter columns or build condensate and settling tanks.