Opticlean B inorganic fouling and scaling RO membrane

$352.11

Specification: White powder

pH (1% solution): 10.5-11

Standard package: 45 lbs/22.72 kg

OptiClean™ B is a high pH powdered cleaner that combines chelants and solubilizing agents designed specifically to remove organic, particulate and other acid insoluble foulants. Used in a program that includes an acidic cleaner for scale and metal hydroxide removal, this highly efficient product provides excellent foulant removal resulting in longer system run times and increased membrane life expectancy

Opticlean B inorganic fouling and scaling RO membrane

Specification: White powder

pH (1% solution): 10.5-11

Standard package: 45 lbs/22.72 kg

OptiClean™ B is a high pH powdered cleaner that combines chelants and solubilizing agents designed specifically to remove organic, particulate and other acid insoluble foulants. Used in a program that includes an acidic cleaner for scale and metal hydroxide removal, this highly efficient product provides excellent foulant removal resulting in longer system run times and increased membrane life expectancy

The application is especially suitable for membranes of these manufacturers: Dupont (Dow Filmtec-USA), LG-Chem (Korea), Toray (Japan), CSM (Korea), Hydranautics (USA), Vontron (China)….

Features / Benefits

- Readily dissolvable powdered cleaner provides efficient shipping and handling

- Phosphate-free formula to reduce negative impact on the environment

- Buffered pH to maintain optimum cleaning performance throughout cleaning cycle

- Best results when used in a program that includes either OptiClean™ A or Lavasol ™ 1

Uses

- For use on reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF) and micro-filtration (MF) membranes

- Formulated to dissolve organic precipitants from the membrane surface

- To aid in the removal of particulate, colloidal, microbiological and other acid insoluble foulants from the membrane surface

When do I Clean?

When any ONE of the following changes :

– NPF = Normalized Permeate Flowrate by 10 – 15%

– NDP = Normalized Differential Pressure by 10 – 15%

– NSP = Normalized Salt Passage by 10 – 15%

▪ Exceeding these limits may become irreparable !

▪ Plan your cleaning activity proactively

▪ Determine your plant’s true cleaning frequency & stick to it

Calculating Cleaner Quantity RO 8inch:

✓ Lower water usage = lower cleaner quantity --> more competitive

✓ Total cleaning solution volume required based on :

– membranes holding volume

– piping volume

– CIP tank volume

Using a 50L (or larger capacity) for CIP tank, put the clean water after RO into this tank with a capacity of 43L, then pour the membrane wash package R0-8040A into it and stir to dissolve completely. Solution pH 2.5-3.5

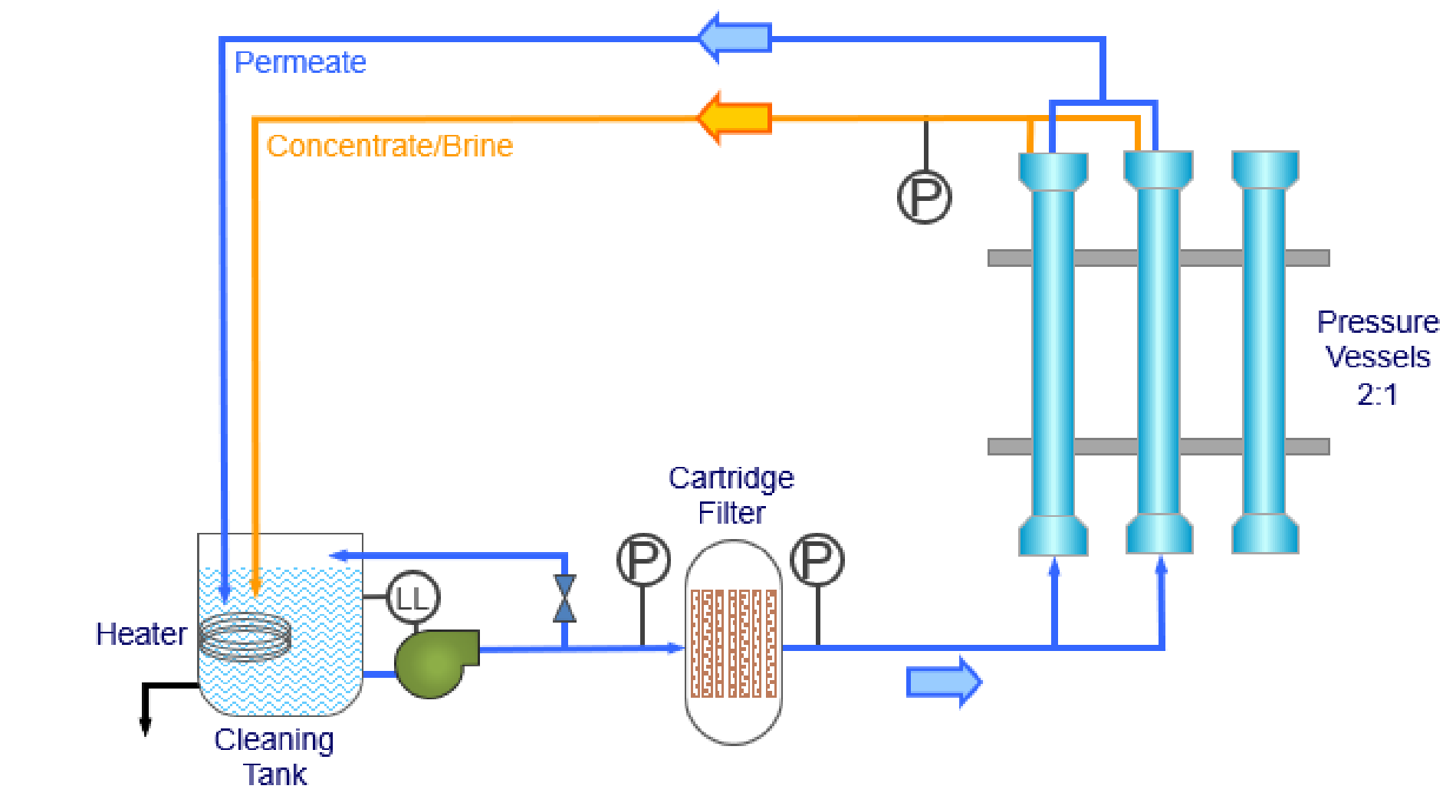

The standard CIP scheme is as follows:

- The CIP chemical solution flow operates in the same direction as the filtration process. The circulation time of the CIP chemical solution is from 30-90 minutes. Recommended CIP for each Stage. Maximum flow 152 liters/min for 8 inch RO membrane. The maximum cleaning pressure is 60 psig (4.2 bar).

- In case the RO membrane is severely clogged, at the initial CIP should separate the stream to remove 10-20% of the membrane washing solution to avoid the residues that have separated from the membrane and then stick on the membrane surface. When re-operating the RO system, the finished water stream after being filtered must be drained to ensure that the residual membrane washing chemicals are completely removed from the system.

- Clean the membrane with RO water before starting the system again

Choosing the right membrane cleaning chemical is very important because frequent and careless cleaning will shorten the life of the membrane, and sometimes the wrong choice of cleaning chemicals can stain the membrane again faster and reduce membrane life. Cleaning will be more effective if it is tailored to each individual film condition.