Antiscalant chemical SpectraGuard 360

$229.54

– Package: tank 18.9 L

– Weight: 20.4 kg

– Specific gravity: 1.00 – 1.2 kg/l

– pH (Liquid 1%): 2.0 – 2.8

– Specification: Amber liquid

– Origin: PWT -Mỹ

Application to control CaCO3, CaSO4, BaSO4, CaF2, Hydroxide of Fe/Mn, CaHPO4, Silica

----> Giảm ngay 5% tổng đơn hàng khi mua trên 10 đơn vị sản phẩm. Vui lòng đăng nhập vào giỏ hàng và thanh toán để nhận ngay ưu đãi

Thanh toán bằng MoMo giảm ngay 2% - Xem giỏ hàng

Category: Antiscalant chemical

Antiscalant chemical SpectraGuard 360

– Package: tank 18.9 L

– Weight: 20.4 kg

– Specific gravity: 1.00 – 1.2 kg/l

– pH (Liquid 1%): 2.0 – 2.8

– Specification: Amber liquid

– Origin: PWT -Mỹ

Application to control CaCO3, CaSO4, BaSO4, CaF2, Hydroxide of Fe/Mn, CaHPO4, Silica

Features and benefits of anti-scale chemicals

- Using a proprietary blend of polymers and phosphonates increases membrane fouling control due to high salt, silica and colloidal water content.

- The higher efficacy allows lower doses to be used than current chemicals.

- Solid molecular structure helps maintain stability under high pH, high temperature and high salinity conditions

- Certified to ANSI/NSF 60

How to use anti-scale chemicals

- Directly mixed into the input water, has anti-scale effect for RO membrane / NF membrane, protects and increases the life of the membrane, reduces the time and cost of rinsing the membrane later

- For better effect, it is necessary to combine with the company’s chemicals

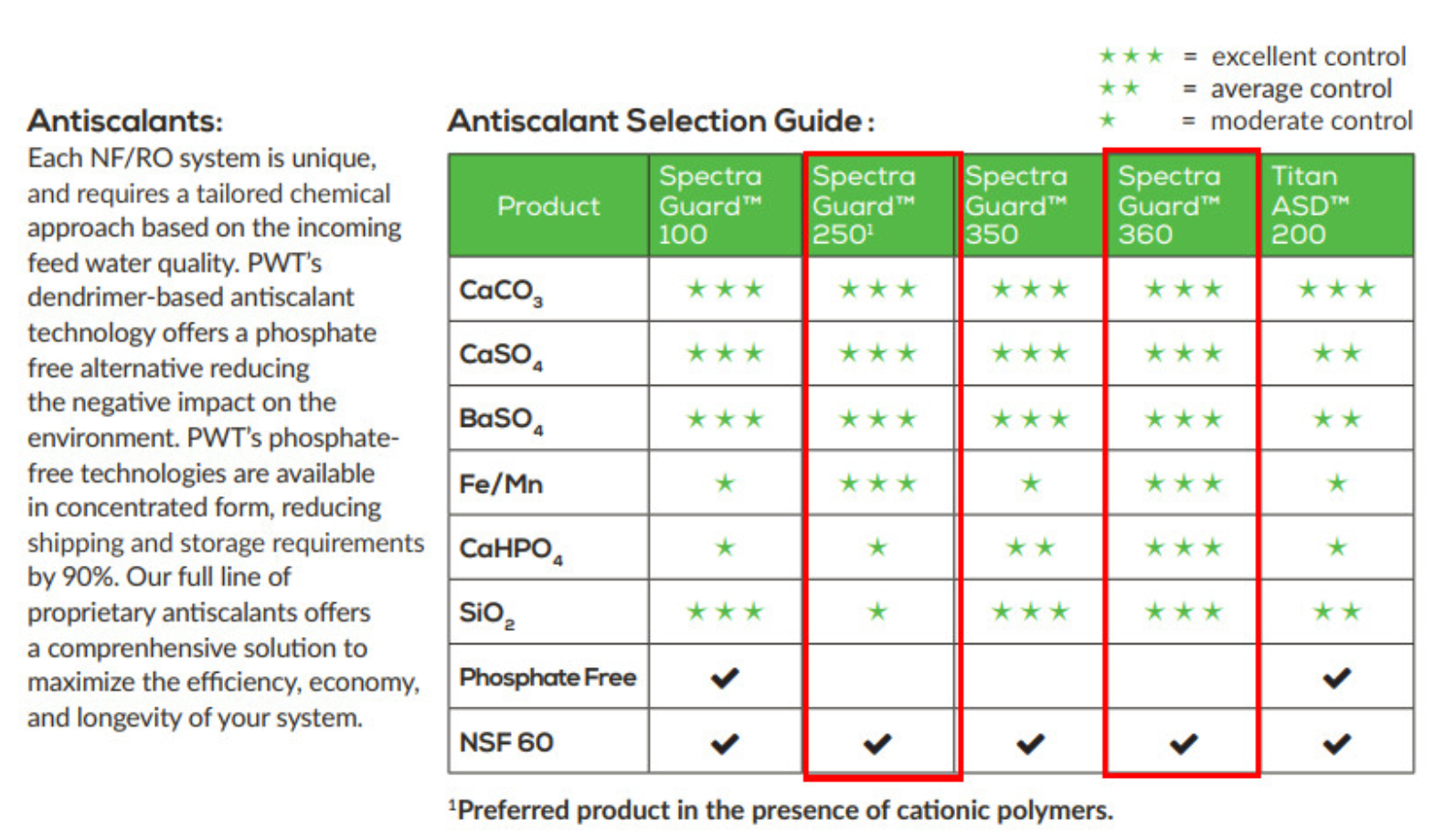

Compare Antiscalant chemical SpectraGuard 250 and 360

To determine the correct dose of anti-scale chemical, please refer to the following utility:

Antiscalant chemical dosing calculator for RO membrane

Input Data

| Feed water flowrate before RO membrane | m3/h | |

| Permit water flowrate after RO membrane | m3/h | |

| Dose of antiscalant chemical (Normally from 1-5mg/l based on feed water quality) |

mg/L | |

| Operation time | h/day | |

| Chemical mixing cycle | Day/time | |

| Chemical storage tank | L |

Result

| Antiscalant chemical consumption per day | 0 | Kg/day |

| Antiscalant chemical need to fill in the mixing tank | 0 | Kg |

| Recovery of RO system | 0 | % |

| Antiscalant chemical concentration after mixed | 0 | % |

| Dose of antiscalant chemical after mixed | 0 | L/h |

See more: How to use utility software to calculate antiscalant chemical dosing for RO membrane

Related products

-8%