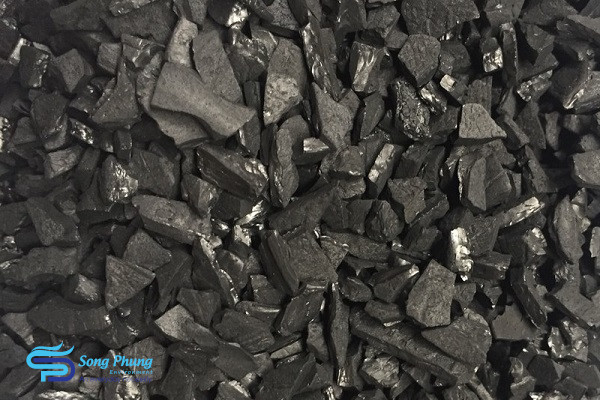

ODM-2F filter media

$1.63

ODM-2F filter media

– Specification: 40lit/bag

– Particle size: 0.8-2.0mm

– Density: 650kg/m3

– Surface area: 120-180 m2/g

– Porosity: 70%

– Absorption capacity: 1.3g/g

– Water immersion: 90-95%

ODM-2F filter media

– Specification: 40lit/bag

– Particle size: 0.8-2.0mm

– Density: 650kg/m3

– Surface area: 120-180 m2/g

– Porosity: 70%

– Absorption capacity: 1.3g/g

– Water immersion: 90-95%

– Origin: Russia

Specification:

– Country of manufacture: Russia. The product is patented by the Patent and Trademark Administration of the Russian Federation, No. 2141375, dated December 15, 1998.

– Multipurpose filter material ODM-2F is a natural product (main components are diatomite, zeolite, benonnit) activated at high temperature, put into application in 1998 in many projects in Russia and many other countries. . Used in Vietnam since 2002.

– Scope of application: can simultaneously replace quartz sand, catalyst particles and activated carbon in the technological process of water and wastewater treatment. The product is certified safe for domestic and drinking water use.

– Properties: as absorbent, absorbent and multi-purpose filter material.

– Basic chemical composition: SiO2 <= 84%; Fe2O3 <= 3.2%; Al2O3 + MgO + CaO = 8%;

Application:

– Raise and stabilize the pH of water in the range of 6.5-8.0

– Catalyze the reduction of iron (Fe < 35 mg/l)

– Reduce the content of nitrogen (nitrite, nitrate, ammonium), phosphate (20-50% depending on the filtration speed from 4-7 m/h), capable of reducing arsenic, reducing fluorine in water (the effect is similar to catalyst particles). Alumina works).

– Reduce the content of some organic compounds in water

– Removal of heavy metals such as copper, zinc, chromium, nickel

– Reduced oil content (absorption of about 90 mg of oil/g seed)

– Eliminate radioactive substances

Advantage:

– Combine many treatment stages such as catalysis, flocculation, sediment filtration in the same device.

– Increase safety for water quality after treatment

– Simple to operate

– The price is much lower than other adsorbents

– It is possible to replace the filter materials being used without changing the filter tank structure.

– The amount of filtered water is lower than other materials

Condition uses:

– pH input >= 6. In case of pH < 6, it is recommended to filter in combination with pH lifting beads (LS) or raise pH with chemicals (optimal pH for iron reduction is 6.5). Input iron content <=35 mg/l

– Filtration speed: 5-20m/h. Can be used in open filter tanks or pressurized filter tanks. Filter direction from top to bottom.

– ODM-2F granules do not need to be reconstituted (except for the defluorine process). After a period of use about 3-5 years (depending on the quality of the source water and treatment requirements) it is necessary to replace the seeds.

Recommended use:

– The filter speed and layer thickness of the ODM-2F filter material will be adjusted according to the iron content or pollutants present in the water. To treat groundwater, it is advisable to arrange aeration, aeration or ejector equipment in front of the filter tank to provide more oxygen during iron oxidation.

– To increase the treatment efficiency for water with low pH, it is recommended to combine with pH lifting beads (LS). The LS particle layer thickness is adjusted according to the pH of the water source and the filtration rate. Or use with chemicals to raise pH such as NaOH, Na2CO3, lime.

– To create clarity for the water, it is necessary to arrange under the ODM-2F layer a layer of quartz sand 0.2-0.3m thick.

– In equipment for reducing iron with high content over 5 mg/l: should arrange ODM-2F layer height of at least 0.8m, filtration speed should not exceed 20m/h. The treatment effect will be better after 3-4 days of operation (the first time to create a catalyst surface on the particle surface)

– In the case of underground water containing iron in the form of organic complexes, a little chlorine can be added before the ODM-2F filter tank.

– ODM-2F seeds have the ability to treat oil in water with oil concentration up to 20mg/l. The oil absorption capacity of the seeds is 90mg/g .

– It is necessary to wash ODM-2F seeds before putting them into use.

– Wash the filter periodically by backwashing process. Backwash cycle 1-2 times/day.night. The intensity of washing water to ensure the expansion of the filter material layer reaches 30% is 10 l/s.m2. Filter wash time 15-20 minutes. No need for aeration.